Coolant Recycling Technology

Coolant Recycling Technology

Industry-first recycling system for spent engine coolant

The Process:

Queensland-developed solution for reclaiming & recycling spent coolant

The Product:

Coolwash: biodegradable, performance-based, safe cleaning detergent

Solutions – urban mining in practice

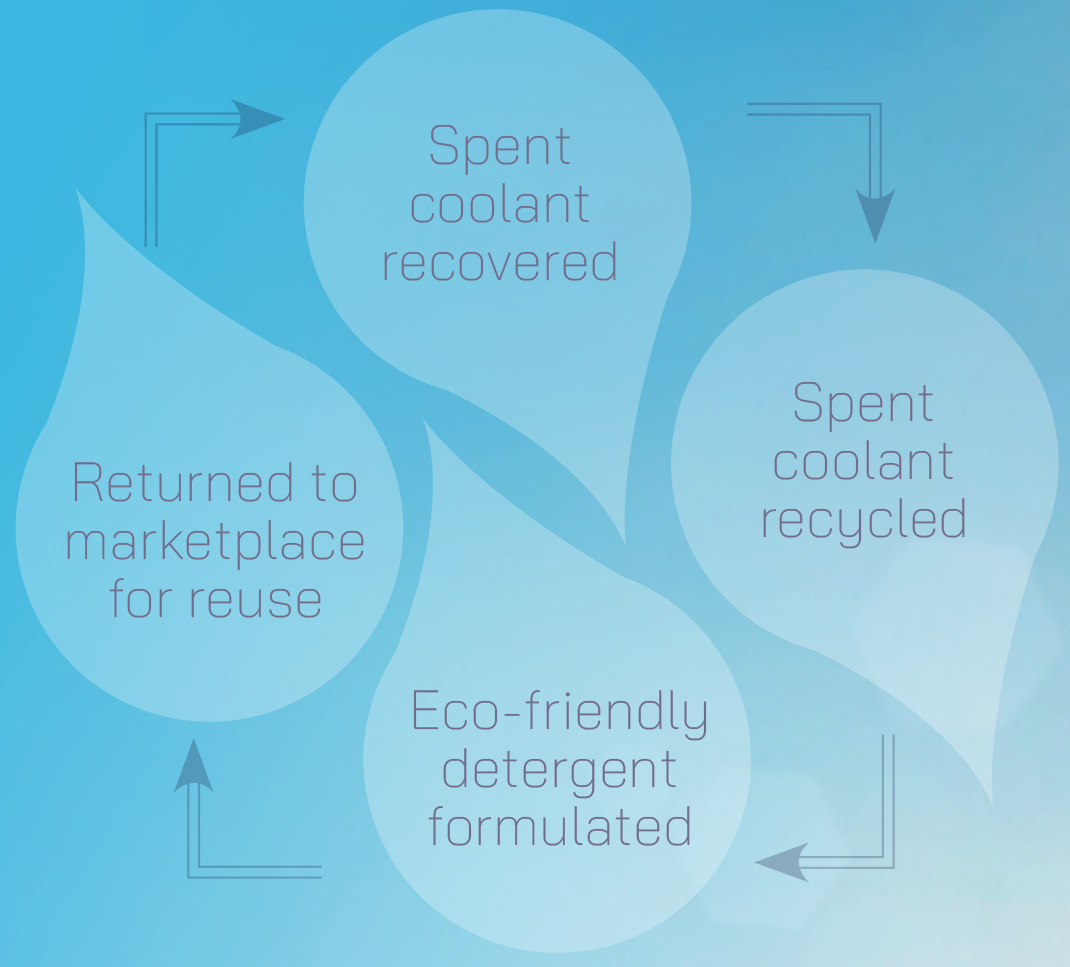

Coolant Recycling Technology (CRT), developed by Prochem Group of Companies, is the first of its kind for the region. By reclaiming and recycling spent engine coolant in heavy industrial and mining environments, the CRT system converts the waste product into a biodegradable, performance-based, safe cleaning detergent. Prochem is proud to offer this solution to mining and heavy industry.

Decades of experience in coolant handling

Prochem boasts two decades of experience supplying coolant packages in Australia and the owners have developed a strong understanding of the required technology, handling skills, patterns of use and disposal issues associated with these products. This affordable, efficient & sustainable coolant recycling program offers all generators of waste coolant, and in particular large mining companies, a service backed by experience, knowledge, and data.

COOLANT RECYCLING TECHNOLOGY (CRT)

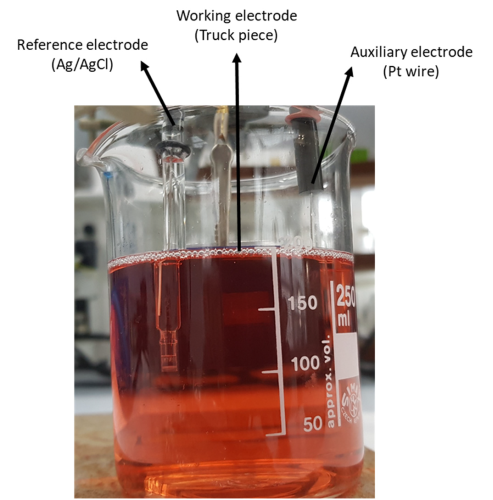

How does the Coolant Recycling Technology (CRT) work?

- Coolant type and application recorded

- Biodegradability of spent coolant confirmed before receipt (only propylene glycol-based products accepted)

- Trade waste certificate supplied to customer

- Coolant recovered from site through primary filtration system – cost per litre based on quantities supplied

- Transported to our Mackay production facility

- Volume and origin information transferred to production facility as part of record keeping process

- Waste from this process is recovered and disposed of by licensed waste company to approved landfill or incineration

- All tramp oil, heavy metals and heat affected components removed by chemical treatment and filtration

- Components used in re-engineering process are selected based on biodegradability, performance, safety, and environmental impact

- Finished products are logged into traceability system, labelled with a recycled logo and returned to market as COOLWASH

COOLWASH

COOLWASH – the detergent that ticks all the right boxes!

- Manufactured from recyclable products

- Built-in, scientifically proven corrosion protection

- Fast acting, free rinsing, and no streaks cleaner

- Suitable for use in conjunction with most coalescing plate separators

- Suitable for use in HV & LV foam applicators

- Safe on all metal surfaces

- Will not attack paintwork or chrome

- Deemed a Non-Hazardous Chemical and Non-Dangerous Goods by WHS regulations and ADF Code

- Manageable detergent usage

Coolwash Technical Data Sheet

We’ve partnered with recognised researchers to deliver an exceptional solution for business

- COOLWASH boasts scientifically proven corrosion protection to painted and unpainted metal surfaces increasing lifecycle of plant and equipment.

- COOLWASH assists in reducing corrosion in wiring looms, harnesses etc – green death.

- COOLWASH provides a solution for the recovery of a problem waste stream such as spent engine coolant.

- COOLWASH provides an opportunity to recycle and reuse discarded products.

- COOLWASH reduces the cost of production.

- COOLWASH reduces infrastructure costs associated with maintaining pipework, cladding, walkways at washpads, drive-through LV facilities wastewater treatment systems and more.

- COOLWASH lends itself to environmentally acceptable work practices.

Research-backed data and results

Prochem was so confident in this coolant handling system that it partnered with world-leading researchers at James Cook University over several years to undergo testing and analysis of the technology with much success. To learn more about the results of this comprehensive research and findings, contact us today. We look forward to showing new and existing customers the amazing results this technology has in cost-efficiencies and biodegradability.

Environmental sustainability

Coolant disposal is often a time-consuming & environmentally risky process for business owners, not to mention the increasing costs. Through ongoing product development, we strive to continually find ways to minimise the environmental impact of all our products whilst retaining quality. We take our commitment to ethical and environmentally sustainable products and services seriously, so you can rest assured that when you work with us, you are making a responsible choice.

IN THE MEDIA

CSIRO

‘Prochem Agencies: Fighting mine vehicle corrosion using vehicle waste’

Greater Whitsunday Alliance (GW3)

‘The Master of reinvention’

Australian Mining Review

‘Waste Materials: Supporting A Sustainable Approach To Corrosion Inhibition At Mine Sites’

Prochem is dedicated to serving the needs of the resources industries including coal, oil, gas, minerals processing, iron/steel, as well as industrial distribution centres and government and environmental regulators. We also specialise in site-specific environmental services such as water treatment, collection and recycling processes, spill response equipment, training and preventative maintenance services as well as bio-remediation.

SOLUTIONS FOR INDUSTRY

How can this recycling technology improve your business? Contact us today to discover the many benefits of CRT and the COOLWASH product.

PROVEN RESULTS • DEVELOPED IN REGIONAL QLD • RECOVERY | RECYCLE | REUSE • ENVIRONMENTALLY FRIENDLY • WATER REDUCTION BENEFITS • INNOVATIVE APPROACH • FULLY TRACEABLE